By Jayne Sebright, Center for Dairy Excellence Executive Director

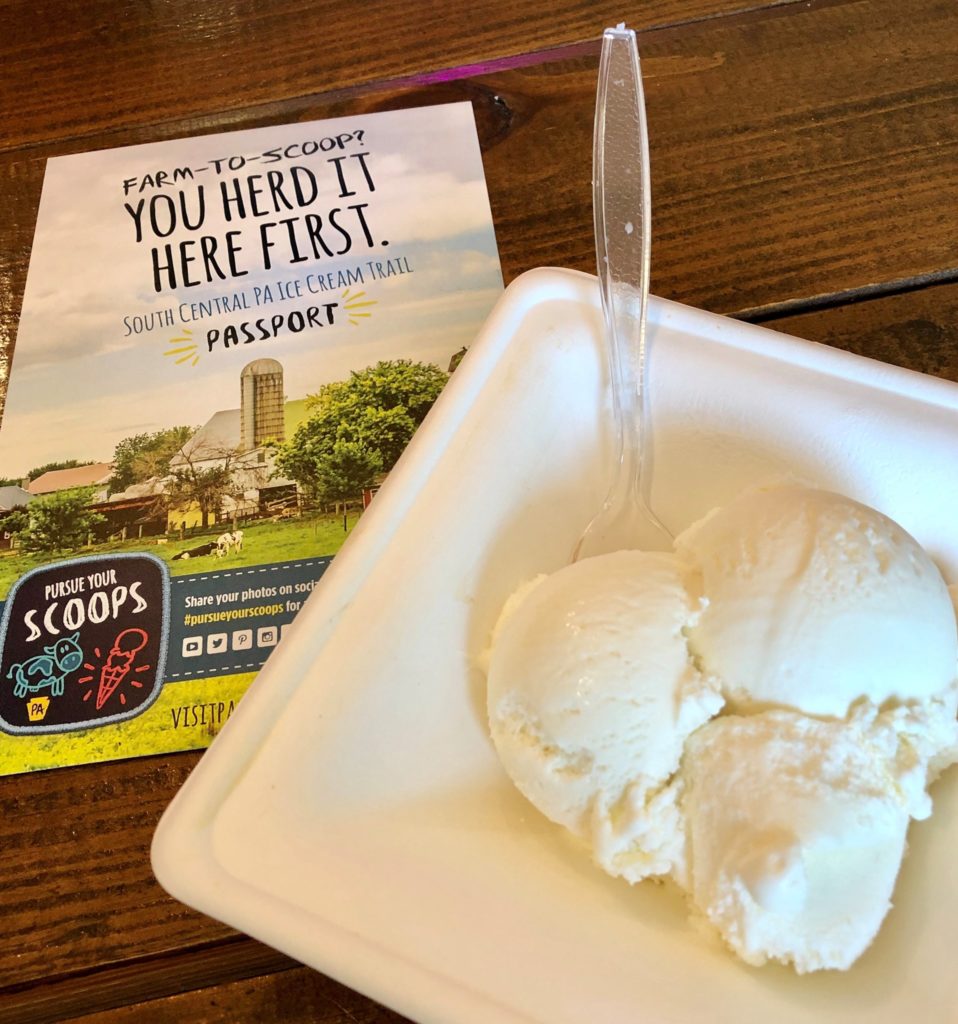

Thirty-five years ago, US President Ronald Reagan proclaimed July as National Ice Cream Month. Since then, people across the country have celebrated the creamy treat and its ability to brighten almost anyone’s mood. Last year the Center worked with Pennsylvania’s Tourism Bureau and the Pennsylvania Department of Agriculture to launch the Pennsylvania Ice Cream Trail, showcasing creameries that offered a true farm-to-cone experience. To add some excitement and engagement to the trail, participants received a stamp on their “passport” at each creamery they visited, which they could redeem for fun prizes.

The effort was a huge success, with more than 1,500 passports redeemed through the campaign last year. This year, the trail was expanded to include a Western, South Central and Eastern Pennsylvania trail with more than 30 creameries involved. Right now, completed passports are piling up in our office, with people across Pennsylvania clamoring to get stamps from enough creameries to win their prized Ice Cream Trail t-shirt prior to the September 2nd deadline.

This promotion does a great job at getting people out to creameries where they can enjoy a farm experience. But what amazes me most about it is how passionate people are about their ice cream. It continues to create a buzz of media attention and excitement in unexpected places. One gentleman even used the Ice Cream Trail as the platform to propose to his future wife, and now they’re incorporating samples of ice cream from their favorite creameries into their wedding reception.

I eat ice cream almost every day all year long, so I don’t need a month to remind me to enjoy it. What National Ice Cream Month does remind me of, though, is an article I first heard at my high school graduation 30 years ago. It is called “The Station” and written by Robert J. Hastings. It talks about how we spend so much time worrying about “The Station” in life – when we graduate, when we succeed in life, when our kids graduate – that we forget to enjoy the journey of life itself.

Climb More Mountains

Like many farm wives, I have both an off-farm job and responsibilities on the farm. Our weekends are often spent on the farm between milking and things like cleaning pens, spraying weeds and other chores that didn’t get done through the week. This past weekend, though, after prodding from my 12-year-old, we went hiking at a nearby state park.

It has probably been five years since I went hiking, and I realized about halfway up the trail that my body was far more out-of-shape than the last time I went. But once we got to the top, I was so glad we took the time to go. It was beautiful, and every worry I had faded away as I looked across the mountain range and enjoyed God’s creation. Afterwards we went swimming in the nearby lake and got—you guessed it—ice cream on our way home. It was a great day.

The reason “The Station” sticks in my mind 30 years after hearing it is that Hastings describes days just like the one I had—days we need more of. He ends his article with, “So stop pacing the aisles and counting the miles. Instead, swim more rivers, climb more mountains, kiss more babies, count more stars. Laugh more and cry less. Go barefoot oftener. Eat more ice cream. Ride more merry-go-rounds. Watch more sunsets. Life must be lived as we go along. The Station will come soon enough.”

For those of us who have been working in dairy over the past few years, it may seem like the Station is never going to arrive. Whether you’re a dairy farmer or you are someone in the industry working to help dairy farm families, we are all waiting for that day when milk prices increase, our farms become more profitable, and new market opportunities develop — that day when we can say we have arrived and the industry is great again.

It’s About the Journey

But what Hastings reminds us in his article is that the Station is an illusion that constantly outdistances us. He challenges us to relish the everyday moments and remember Psalm 118:24, “This is the day which the Lord hath made; we will rejoice and be glad in it.”

Right now, we are starting to see milk prices increase, with June’s Class IV milk price at its highest level in 43 months. But there is no guarantee those prices will continue to rise. Even if they do, issues with trade and weather-related uncertainty could challenge feed costs this fall. We must continue to focus on our goals, manage our cost of production and work toward where we want to be. We need to recognize that the Station may continue to outpace us.

Every day I witness the stress that the financial uncertainty has placed on our farm families. You cannot continue to carry that stress without taking care of what matters most — your health and your own personal well-being. Eat more ice cream, climb more mountains, and find more ways to live in the moment. It’s the little things that will help you stay positive even in challenging times.

If you do feel overwhelmed, find people you can lean on for guidance and support, whether it’s a loved one, friend, or your pastor. Don’t ever try to carry the burden on your own. For those who are feeling overwhelmed and aren’t sure where to turn, the Center can connect you with resources that can help. Call us at 717-346-0849 or visit our website.

Editor’s Note: This column is written by Jayne Sebright, executive director for the Center for Dairy Excellence, and published monthly in the Lancaster Farming Dairy Reporter.

Follow along with our Center Focus Column each month.